product categories

-

- Hooks are used in lifting systems as a connection between the load to be lifted and the wire rope or chain slings

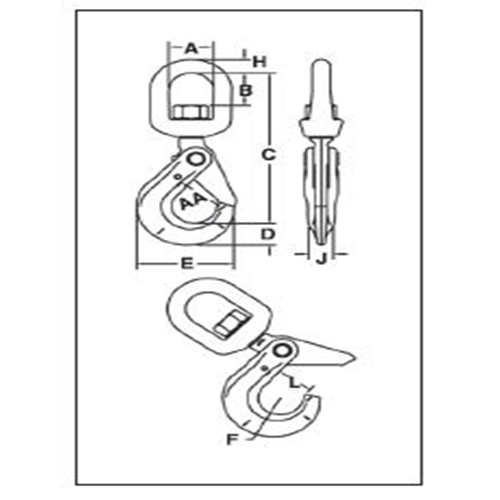

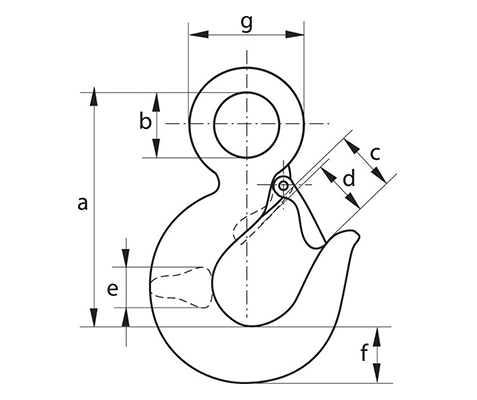

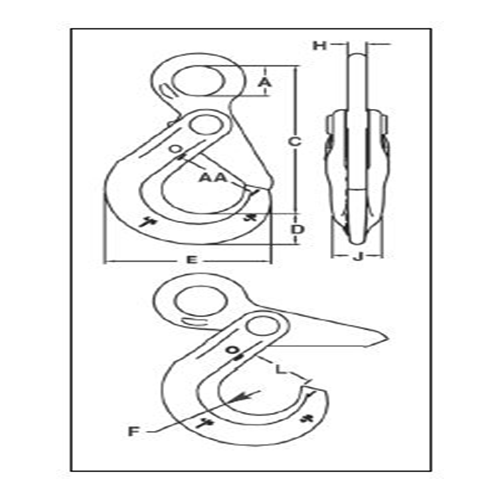

- The Ableforge Sling Hook is a versatile, general purpose hook suitable for most slinging applications and has the added advantage of safety latch kits, readily available, for converting it into an Ableforge safety hook.

-

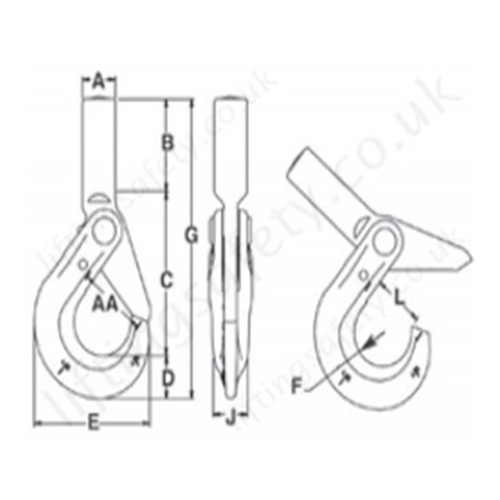

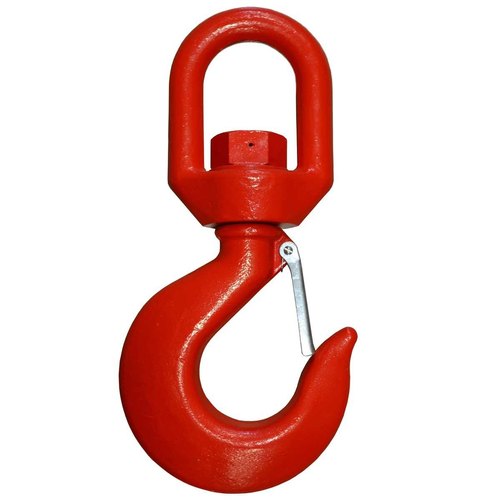

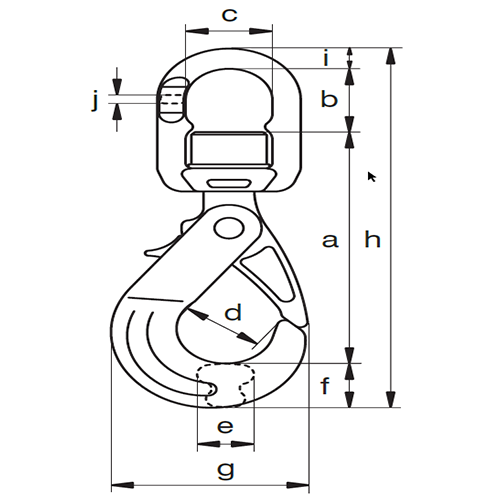

- Hooks are used in lifting systems as a connection between the load to be lifted and the wire rope or chain slings

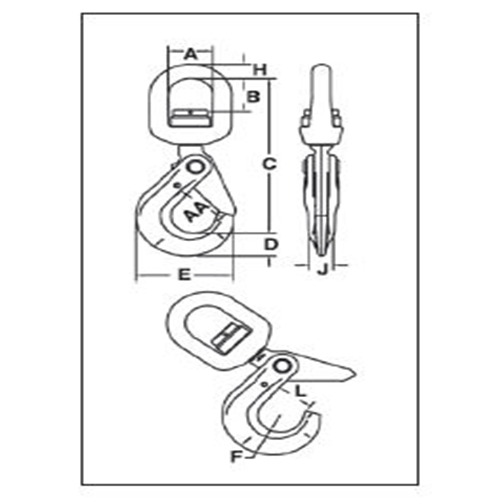

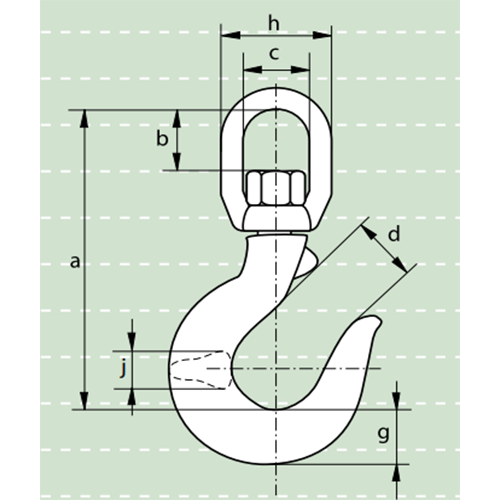

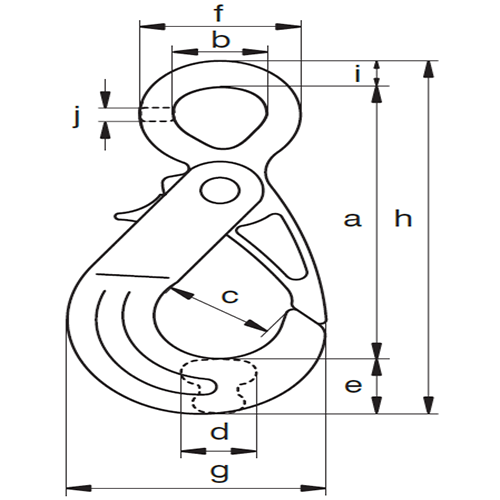

- This Swivel hooks have all the features of an Ableforge Safety Hook, but with the added bonus of its swivel funtion. The swivel assists in the removal of sling leg twist, making it particularly suitable for high-rise lifting.

-

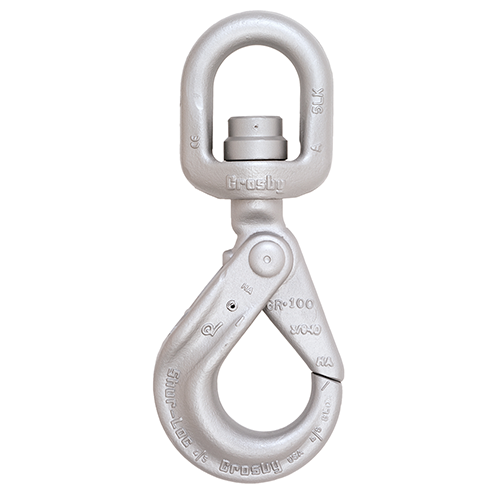

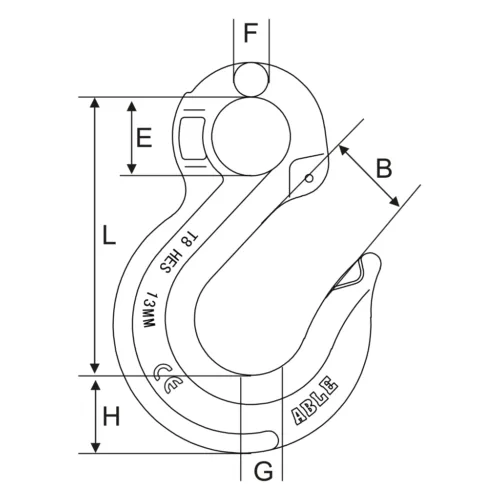

All Crosby 320 Eye Hoist Hooks incorporate the following features:

All Crosby 320 Eye Hoist Hooks incorporate the following features:- The most complete line of Eye hoist hooks.

- Available in carbon steel and alloy steel.

- Designed with a 5:1 Design Factor for (Carbon Steel); 4.5:1 Design Factor for 30t - 60t (Alloy Steel).

- Eye hooks are load rated.

- Proper design, careful forging and precision controlled quenched and tempering give maximum strength without excessive weight and bulk.

- Every Crosby Eye Hook has a pre-drilled cam which can be equipped with a latch. Even years after purchase of the original hook, latch assemblies can be added. (See pages 123 - 125)

- Chemical analysis and tensile tests performed on each PIC to verify chemistry and mechanical properties.

- Type Approval certification in accordance with ABS 2007 Steel Vessel Rules 1-11-17.7 and ABS Guide for Certification on Cranes available. Certificates available when requested at time of order and may include additional charges.

- Hoist hooks incorporate two types of strategically placed markings forged into the product which address two (2)

- Deformation Indicators and Angle Indicators (see following page for detailed definition).

-

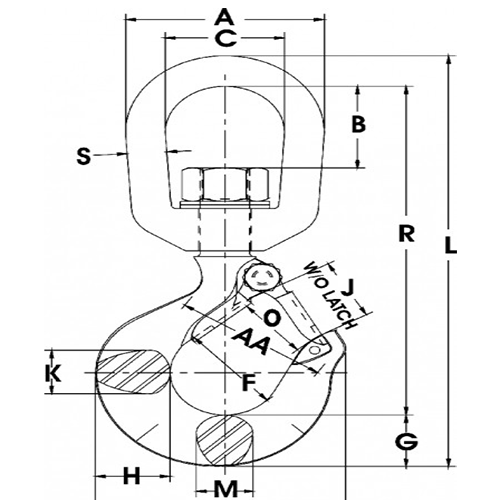

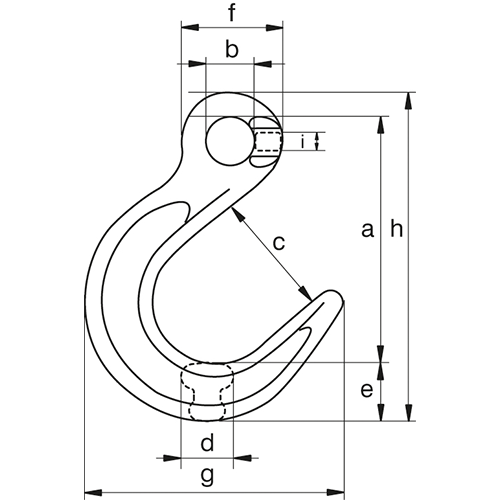

Eye Style incorporates these added features:

Eye Style incorporates these added features:- Individually Proof Tested to 2-1/2 times the 4:1 Working Load Limit with certification.

- S-1316 meets the performance requirements of EN1677-3:2001

- 25% stronger than Grade 80.

- Suitable for use with Grade 100 and Grade 80 chain.

- Designed with “Engineered Flat” to connect to S-1325 chain coupler.

-

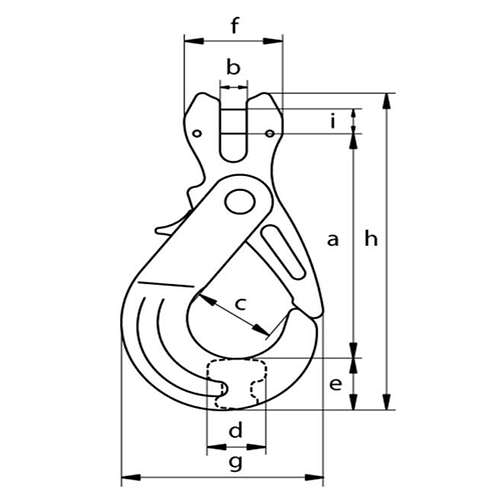

Eye Style incorporates these added features:

Eye Style incorporates these added features:- Individually Proof Tested to 2-1/2 times the 4:1 Working Load Limit with certification.

- S-1316 meets the performance requirements of EN1677-3:2001

- 25% stronger than Grade 80.

- Suitable for use with Grade 100 and Grade 80 chain.

- Designed with “Engineered Flat” to connect to S-1325 chain coupler.

-

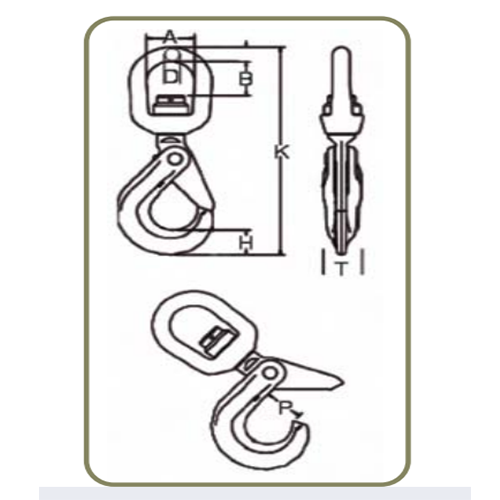

QUIC-CHECK® features:

QUIC-CHECK® features:- Deformation Indicators -- Two strategically placed marks, one just below the shank or eye and the other on the hook tip, which allows for a QUIC-CHECK® measurement to determine if the throat opening has changed, thus indicating abuse or overload.

- Angle Indicators — Indicates the maximum included angle which is allowed between two (2) sling legs in the hook. These indicators also provide the opportunity to approximate other included angles between two sling legs.

- Type Approval certification in accordance with ABS 2007 Steel Vessel Rules 1-11-17.7 and ABS Guide for Certification on Cranes available. Certificates available when requested at time of order and may include additional charges.

-

(2) QUIC-CHECK® features:

(2) QUIC-CHECK® features:- Deformation Indicators — Two strategically placed marks, one just below the shank or eye and the other on the hook tip, which allows for a QUICCHECK® measurement to determine if the throat opening has changed, thus indicating abuse or overload

- Angle Indicators — Indicates the maximum included angle which is allowed between two (2) sling legs in the hook. These indicators also provide the opportunity to approximate other included angles between two sling legs.

-

Instructions for use Lifting hooks should be inspected before use to ensure that:

Instructions for use Lifting hooks should be inspected before use to ensure that:- all markings are legible;

- a hook with the correct WLL has been selected. Refer to the EN 818 standard for Chain Slings for further details;

- the latch is present;

- the latch is functional;

- the bolt, nut or any other locking system cannot vibrate out of position;

- the hook is never side-, tip- or back- loaded;

- swivel hooks may not rotate under load;

- the hooks may not be heat treated as this may affect their WLL;

- never modify, repair or reshape a hook by machining, welding, heating or bending as this may affect the WLL;

- hooks are free from nicks, gouges and cracks;

-

Instructions for use Lifting hooks should be inspected before use to ensure that:

Instructions for use Lifting hooks should be inspected before use to ensure that:- all markings are legible;

- a hook with the correct WLL has been selected. Refer to the EN 818 standard for Chain Slings for further details;

- the latch is present;

- the latch is functional;

- the bolt, nut or any other locking system cannot vibrate out of position;

- the hook is never side-, tip- or back- loaded;

- swivel hooks may not rotate under load;

- the hooks may not be heat treated as this may affect their WLL;

- never modify, repair or reshape a hook by machining, welding, heating or bending as this may affect the WLL;

- hooks are free from nicks, gouges and cracks;

-

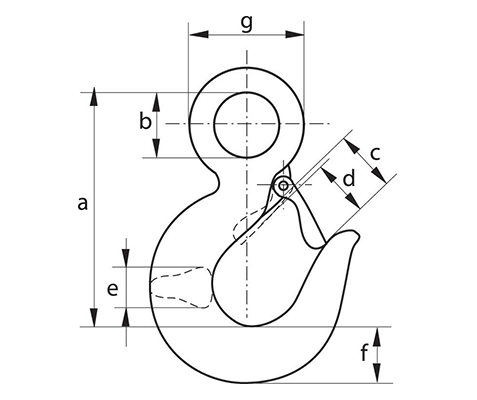

Instructions for use Lifting hooks should be inspected before use to ensure that:

Instructions for use Lifting hooks should be inspected before use to ensure that:- all markings are legible;

- a hook with the correct WLL has been selected. Refer to the EN 818 standard for Chain Slings for further details;

- the latch is present;

- the latch is functional;

- the bolt, nut or any other locking system cannot vibrate out of position;

- the hook is never side-, tip- or back- loaded;

- swivel hooks may not rotate under load;

- the hooks may not be heat treated as this may affect their WLL;

- never modify, repair or reshape a hook by machining, welding, heating or bending as this may affect the WLL;

- hooks are free from nicks, gouges and cracks;

-

Instructions for use Lifting hooks should be inspected before use to ensure that:

Instructions for use Lifting hooks should be inspected before use to ensure that:- all markings are legible;

- a hook with the correct WLL has been selected. Refer to the EN 818 standard for Chain Slings for further details;

- the latch is present;

- the latch is functional;

- the bolt, nut or any other locking system cannot vibrate out of position;

- the hook is never side-, tip- or back- loaded;

- swivel hooks may not rotate under load;

- the hooks may not be heat treated as this may affect their WLL;

- never modify, repair or reshape a hook by machining, welding, heating or bending as this may affect the WLL;

- hooks are free from nicks, gouges and cracks;

-

- Being one of the leading manufacturers in Vietnam in the field of production of Cargo Lashing Belt (Ratchet tie down) with the Dragon brand. United Mekong Holding Company has always focused on safety factors to ensure the load, the quality and reliability with international standards and long time using purpose.

- With a mordern machines system, a team of skilled and senior manpower, we’d like to minimize cost that can help consumers with the most reasonable prices possible. Our Dragon Lashing Belt are always available for different sizes and lengths, it’s suitable to serve for various using purposes of customers.

- There are many options with different colors and widths.

- Easy to use with automatic length adjustment and buckle fastening. Limit damage when transporting goods.

- The material is very durable, ensuring long-term use.

- Cargo can be protected from damage by using hooks specific to each cargo and vehicle characteristics.

-

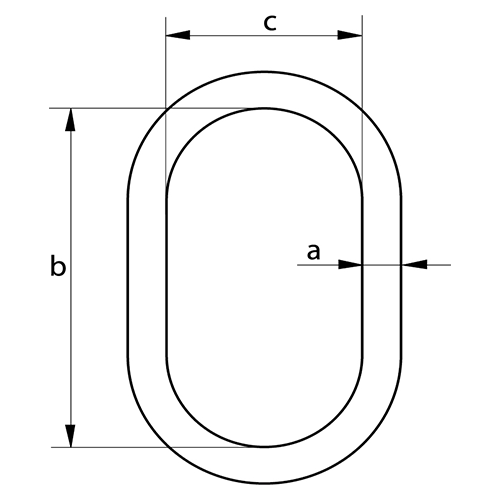

- Masterlink is used in the manufacturing of 1,2,3 and 4-leg slings.

- Mekongsling specialize in supplying masterlink and masterlink assembly for fabricate wire rope slings and single and multi leg chain slings as well.

- The products are cast from alloy steel, with high load capacity and safe for using.

- The Masterlink import from the EU, accompany by quality certificates.

- Inspection should take place at least every six months and more frequendly when the links are used in severe operating conditions

-

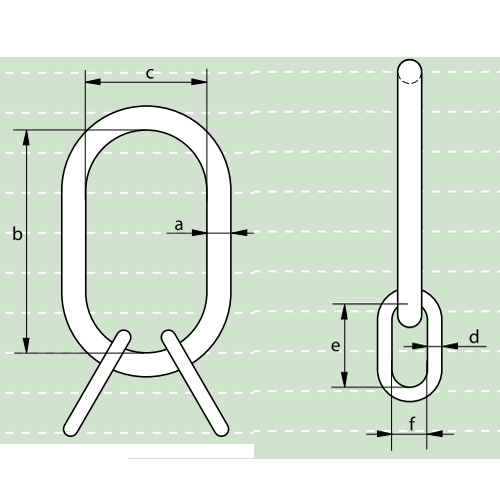

- Masterlink assembly is used in the manufacturing of 1,2,3 and 4-leg slings.

- Mekongsling specialize in supplying masterlink and masterlink assembly for fabricate wire rope slings and single and multi leg chain slings as well.

- The products are cast from alloy steel, with high load capacity and safe for using.

- The Masterlink import from the EU, accompany by quality certificates.

- Inspection should take place at least every six months and more frequendly when the links are used in severe operating conditions.

-

- DNV master links are DNV type approved to certification note 2.7-1, lifting sets for offshore containers, certification no. S-7732.

- DNV master links are designed for use in lifting sets for offshore containers

- Mekongsling specialize in supplying masterlink and masterlink assembly for fabricate wire rope slings and single and multi leg chain slings as well.

- The products are cast from alloy steel, with high load capacity and safe for using.

- The Masterlink import from the EU, accompany by quality certificates.

- Inspection should take place at least every six months and more frequendly when the links are used in severe operating conditions

-

- DNV master links are DNV type approved to certification note 2.7-1, lifting sets for offshore containers, certification no. S-7732.

- DNV master links are designed for use in lifting sets for offshore containers

- Mekongsling specialize in supplying masterlink and masterlink assembly for fabricate wire rope slings and single and multi leg chain slings as well.

- The products are cast from alloy steel, with high load capacity and safe for using.

- The Masterlink import from the EU, accompany by quality certificates.

- Inspection should take place at least every six months and more frequendly when the links are used in severe operating conditions

-

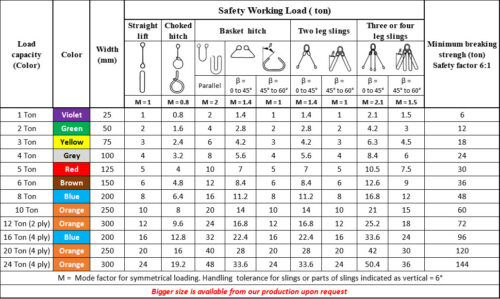

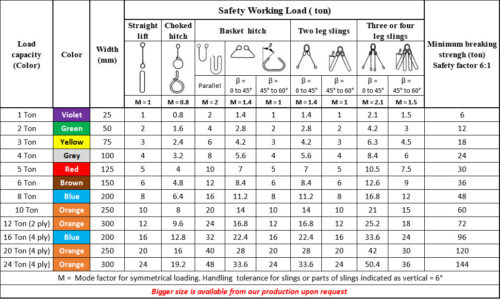

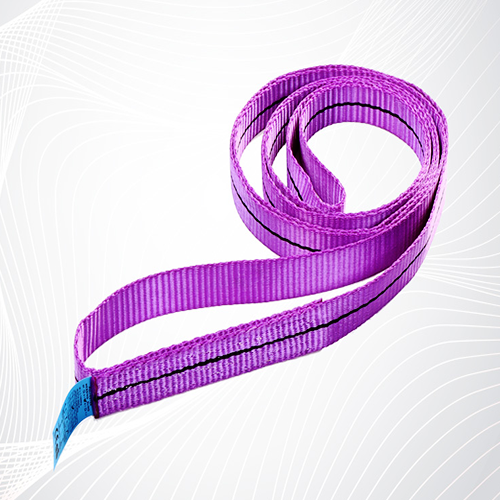

- United Mekong Holding Company is one of the first manufacturer of hight tenacity webbing sling eye to eye & endless in Vietnam. We also imported directly from K Our webbing sling product are proven ahight quality which is conform to BS-EN 1492-1

- United mekong holding company is a distributor of websling with high quality and competitive price.

- For more detailed advice about product and refer to price list, please don’t hesitate contact to us.

-

- Round sling – endless made from 100% Polyester, bigger size upon request, WLL up to 300 tons, color coding on each round sling for added safety, protective sleeving are recommended for round sling when lifting sharp and rough objects.

- For more detailed advice about product and refer to price list, please don’t hesitate contact to us.

- Round sling has two types: eye to eye &

- Application:

- Use for heavy industries, lifting and transfer Pipe, wire rope,, plate steel.

- Types of products are produced from non-ferrrous metals such as copper, lead, aluminum or steel.

- The products sculpture, carvings, handicrafts …

- Machinery and different spare parts

- Cement products, glass, rubber, wood, plastic, paper …

- The stone blocks.

- Cars and other vehicles.

-

- United Mekong Holding Company is one of the first manufacturer of hight tenacity webbing sling eye to eye & endless in Vietnam. We also imported directly from K Our webbing sling product are proven ahight quality which is conform to BS-EN 1492-1

- United mekong holding company is a distributor of websling with high quality and competitive price.

- For more detailed advice about product and refer to price list, please don’t hesitate contact to us.