product categories

-

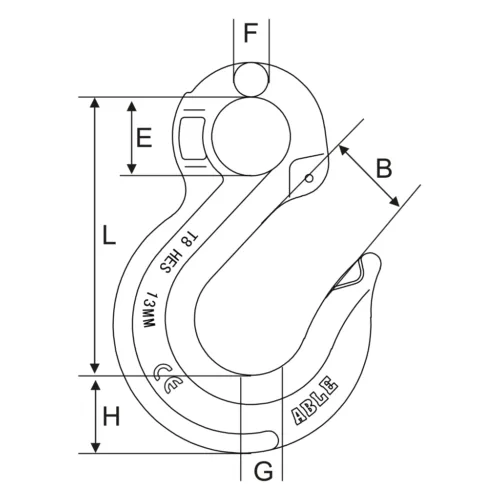

- Hooks are used in lifting systems as a connection between the load to be lifted and the wire rope or chain slings

- The Ableforge Sling Hook is a versatile, general purpose hook suitable for most slinging applications and has the added advantage of safety latch kits, readily available, for converting it into an Ableforge safety hook.

-

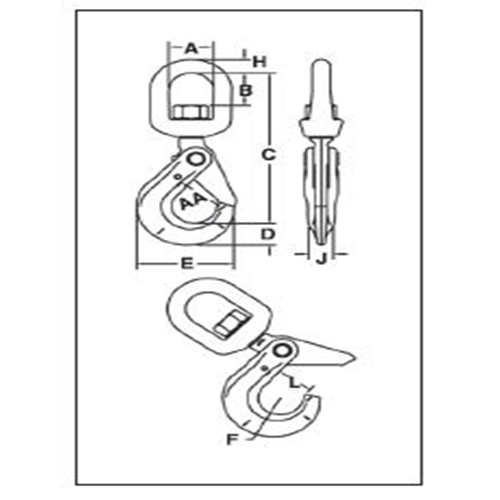

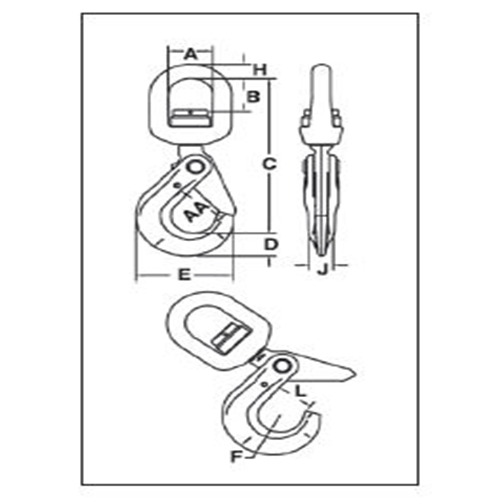

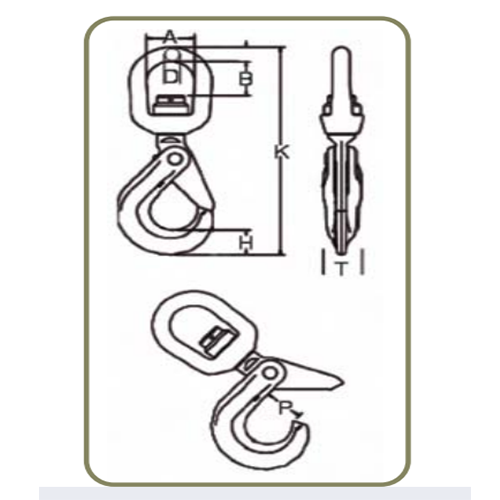

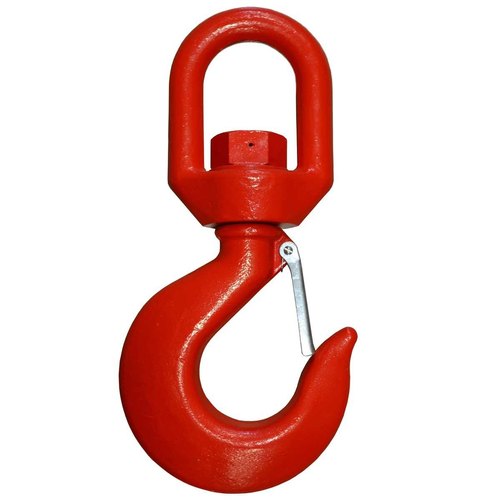

- Hooks are used in lifting systems as a connection between the load to be lifted and the wire rope or chain slings

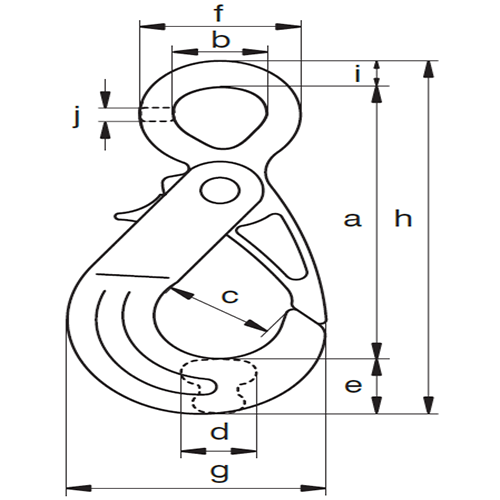

- This Swivel hooks have all the features of an Ableforge Safety Hook, but with the added bonus of its swivel funtion. The swivel assists in the removal of sling leg twist, making it particularly suitable for high-rise lifting.

-

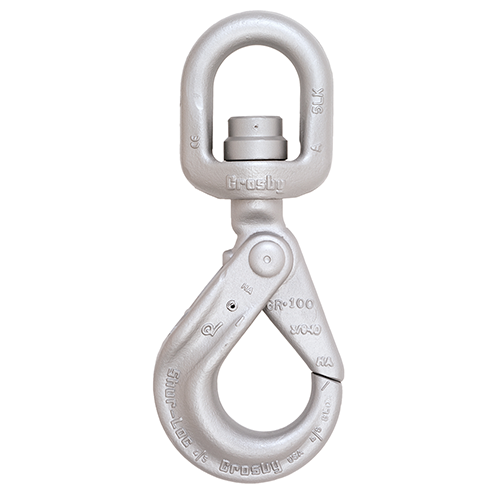

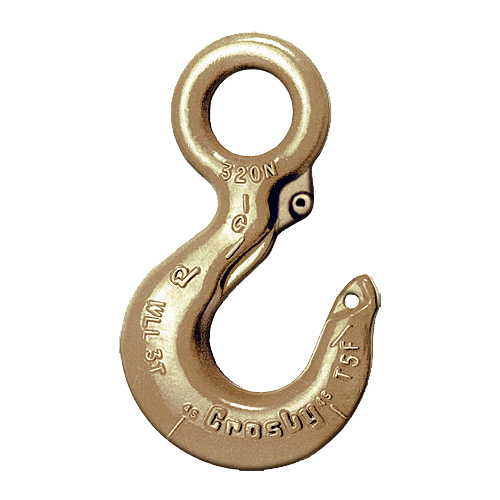

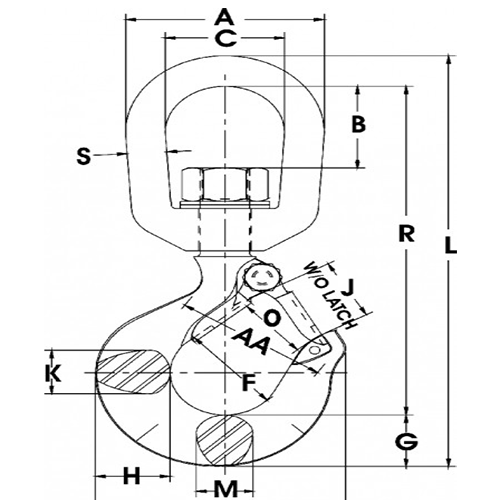

All Crosby 320 Eye Hoist Hooks incorporate the following features:

All Crosby 320 Eye Hoist Hooks incorporate the following features:- The most complete line of Eye hoist hooks.

- Available in carbon steel and alloy steel.

- Designed with a 5:1 Design Factor for (Carbon Steel); 4.5:1 Design Factor for 30t - 60t (Alloy Steel).

- Eye hooks are load rated.

- Proper design, careful forging and precision controlled quenched and tempering give maximum strength without excessive weight and bulk.

- Every Crosby Eye Hook has a pre-drilled cam which can be equipped with a latch. Even years after purchase of the original hook, latch assemblies can be added. (See pages 123 - 125)

- Chemical analysis and tensile tests performed on each PIC to verify chemistry and mechanical properties.

- Type Approval certification in accordance with ABS 2007 Steel Vessel Rules 1-11-17.7 and ABS Guide for Certification on Cranes available. Certificates available when requested at time of order and may include additional charges.

- Hoist hooks incorporate two types of strategically placed markings forged into the product which address two (2)

- Deformation Indicators and Angle Indicators (see following page for detailed definition).

-

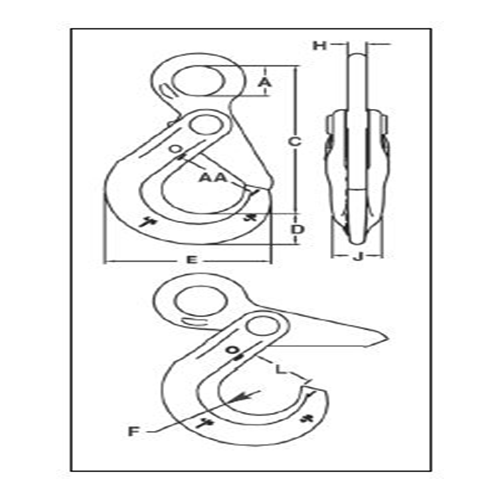

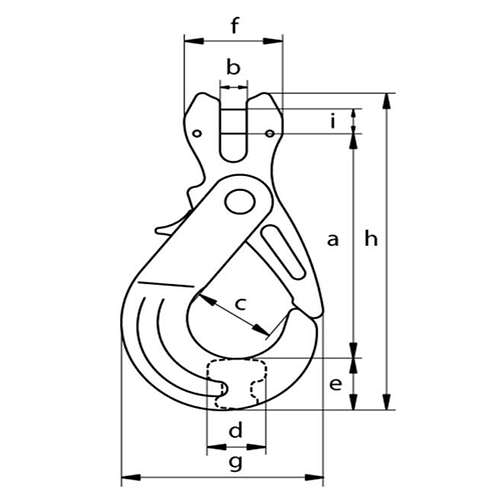

Eye Style incorporates these added features:

Eye Style incorporates these added features:- Individually Proof Tested to 2-1/2 times the 4:1 Working Load Limit with certification.

- S-1316 meets the performance requirements of EN1677-3:2001

- 25% stronger than Grade 80.

- Suitable for use with Grade 100 and Grade 80 chain.

- Designed with “Engineered Flat” to connect to S-1325 chain coupler.

-

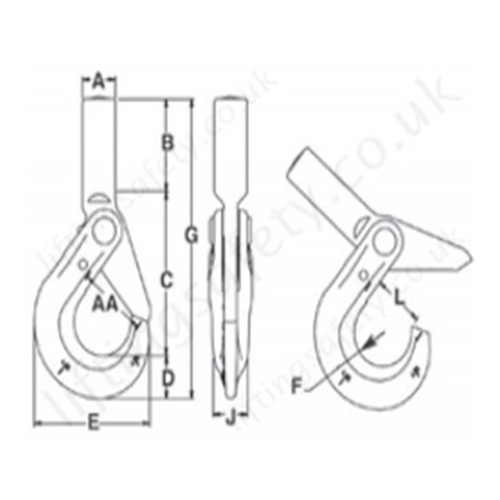

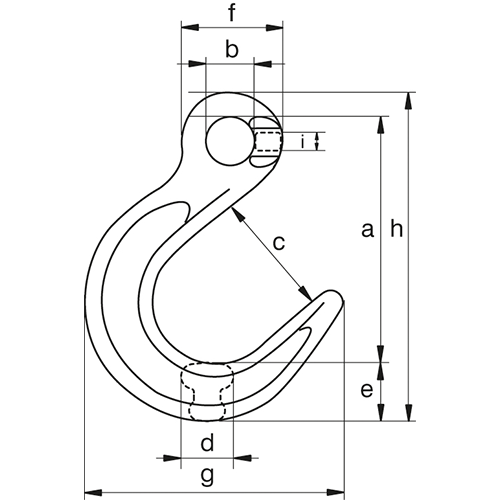

Eye Style incorporates these added features:

Eye Style incorporates these added features:- Individually Proof Tested to 2-1/2 times the 4:1 Working Load Limit with certification.

- S-1316 meets the performance requirements of EN1677-3:2001

- 25% stronger than Grade 80.

- Suitable for use with Grade 100 and Grade 80 chain.

- Designed with “Engineered Flat” to connect to S-1325 chain coupler.

-

QUIC-CHECK® features:

QUIC-CHECK® features:- Deformation Indicators -- Two strategically placed marks, one just below the shank or eye and the other on the hook tip, which allows for a QUIC-CHECK® measurement to determine if the throat opening has changed, thus indicating abuse or overload.

- Angle Indicators — Indicates the maximum included angle which is allowed between two (2) sling legs in the hook. These indicators also provide the opportunity to approximate other included angles between two sling legs.

- Type Approval certification in accordance with ABS 2007 Steel Vessel Rules 1-11-17.7 and ABS Guide for Certification on Cranes available. Certificates available when requested at time of order and may include additional charges.

-

(2) QUIC-CHECK® features:

(2) QUIC-CHECK® features:- Deformation Indicators — Two strategically placed marks, one just below the shank or eye and the other on the hook tip, which allows for a QUICCHECK® measurement to determine if the throat opening has changed, thus indicating abuse or overload

- Angle Indicators — Indicates the maximum included angle which is allowed between two (2) sling legs in the hook. These indicators also provide the opportunity to approximate other included angles between two sling legs.

-

Instructions for use Lifting hooks should be inspected before use to ensure that:

Instructions for use Lifting hooks should be inspected before use to ensure that:- all markings are legible;

- a hook with the correct WLL has been selected. Refer to the EN 818 standard for Chain Slings for further details;

- the latch is present;

- the latch is functional;

- the bolt, nut or any other locking system cannot vibrate out of position;

- the hook is never side-, tip- or back- loaded;

- swivel hooks may not rotate under load;

- the hooks may not be heat treated as this may affect their WLL;

- never modify, repair or reshape a hook by machining, welding, heating or bending as this may affect the WLL;

- hooks are free from nicks, gouges and cracks;

-

Instructions for use Lifting hooks should be inspected before use to ensure that:

Instructions for use Lifting hooks should be inspected before use to ensure that:- all markings are legible;

- a hook with the correct WLL has been selected. Refer to the EN 818 standard for Chain Slings for further details;

- the latch is present;

- the latch is functional;

- the bolt, nut or any other locking system cannot vibrate out of position;

- the hook is never side-, tip- or back- loaded;

- swivel hooks may not rotate under load;

- the hooks may not be heat treated as this may affect their WLL;

- never modify, repair or reshape a hook by machining, welding, heating or bending as this may affect the WLL;

- hooks are free from nicks, gouges and cracks;

-

Instructions for use Lifting hooks should be inspected before use to ensure that:

Instructions for use Lifting hooks should be inspected before use to ensure that:- all markings are legible;

- a hook with the correct WLL has been selected. Refer to the EN 818 standard for Chain Slings for further details;

- the latch is present;

- the latch is functional;

- the bolt, nut or any other locking system cannot vibrate out of position;

- the hook is never side-, tip- or back- loaded;

- swivel hooks may not rotate under load;

- the hooks may not be heat treated as this may affect their WLL;

- never modify, repair or reshape a hook by machining, welding, heating or bending as this may affect the WLL;

- hooks are free from nicks, gouges and cracks;