product categories

-

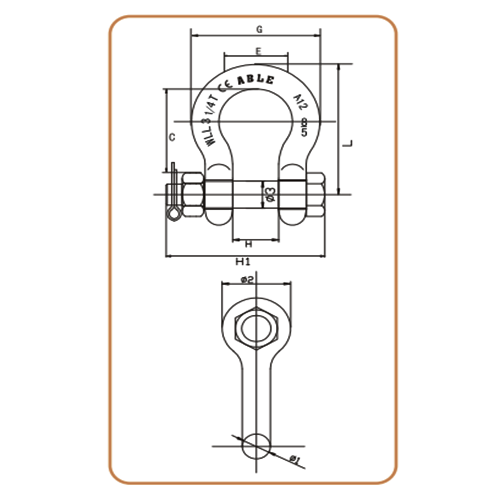

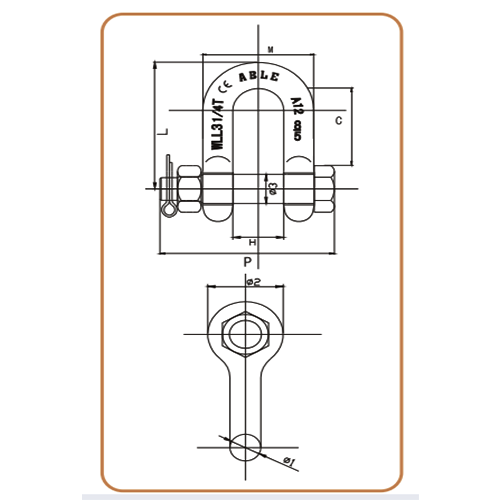

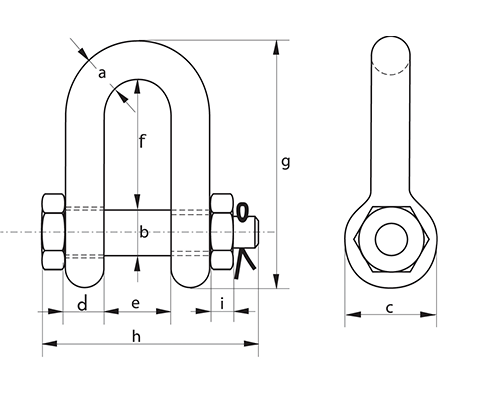

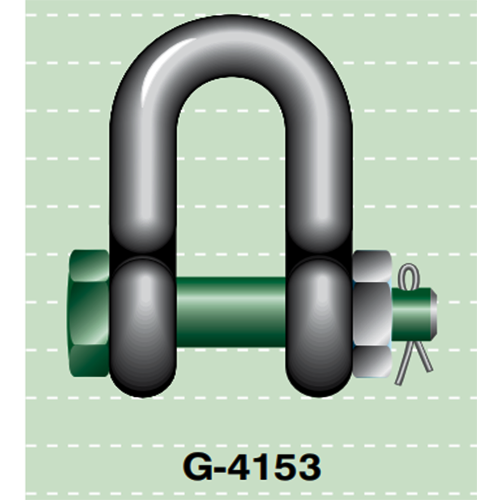

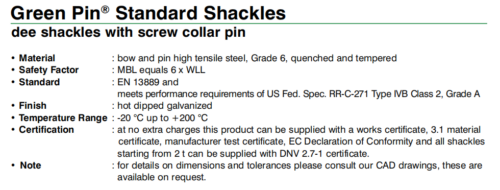

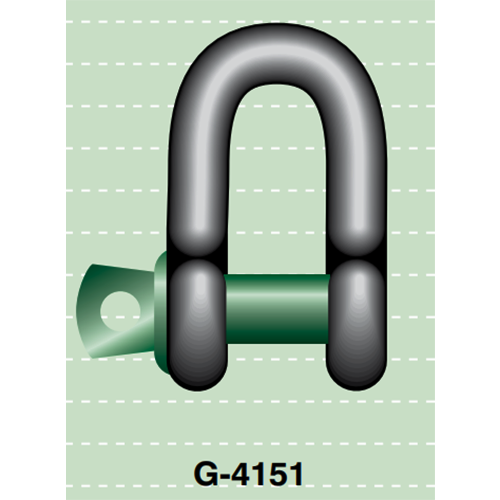

Shackles are used in lifting and static system as removable links to connect (steel) wire rope, chain or other fittings. Screw pin shackles are used mainly for non-permanent applications. Safery bolt shackles are used for long-term or permanent applications or where the load may slide on the pin causing rotation of the pin. We, United Mekong Holding Company, offers a wide range of bow and dee shackles, depending on the application on which the shackle is going to be used; the range stretches from Working Load Limit (WLL) 0.33 tons to 1500 tons. Therefore, our customers have a very extensive range to choose the shackle exactly suitable for the application. Most of the shackles are directly available from stock. Furthermore, shackles can be supplied to many standards such as the US Federal Specification RR-C-271, EN 13889, British Standard 3032, DIN 82101, DIN 82016 ect.

Shackles are used in lifting and static system as removable links to connect (steel) wire rope, chain or other fittings. Screw pin shackles are used mainly for non-permanent applications. Safery bolt shackles are used for long-term or permanent applications or where the load may slide on the pin causing rotation of the pin. We, United Mekong Holding Company, offers a wide range of bow and dee shackles, depending on the application on which the shackle is going to be used; the range stretches from Working Load Limit (WLL) 0.33 tons to 1500 tons. Therefore, our customers have a very extensive range to choose the shackle exactly suitable for the application. Most of the shackles are directly available from stock. Furthermore, shackles can be supplied to many standards such as the US Federal Specification RR-C-271, EN 13889, British Standard 3032, DIN 82101, DIN 82016 ect. -

Shackles are used in lifting and static system as removable links to connect (steel) wire rope, chain or other fittings. Screw pin shackles are used mainly for non-permanent applications. Safery bolt shackles are used for long-term or permanent applications or where the load may slide on the pin causing rotation of the pin. We, United Mekong Holding Company, offers a wide range of bow and dee shackles, depending on the application on which the shackle is going to be used; the range stretches from Working Load Limit (WLL) 0.33 tons to 1500 tons. Therefore, our customers have a very extensive range to choose the shackle exactly suitable for the application. Most of the shackles are directly available from stock. Furthermore, shackles can be supplied to many standards such as the US Federal Specification RR-C-271, EN 13889, British Standard 3032, DIN 82101, DIN 82016 ect.

Shackles are used in lifting and static system as removable links to connect (steel) wire rope, chain or other fittings. Screw pin shackles are used mainly for non-permanent applications. Safery bolt shackles are used for long-term or permanent applications or where the load may slide on the pin causing rotation of the pin. We, United Mekong Holding Company, offers a wide range of bow and dee shackles, depending on the application on which the shackle is going to be used; the range stretches from Working Load Limit (WLL) 0.33 tons to 1500 tons. Therefore, our customers have a very extensive range to choose the shackle exactly suitable for the application. Most of the shackles are directly available from stock. Furthermore, shackles can be supplied to many standards such as the US Federal Specification RR-C-271, EN 13889, British Standard 3032, DIN 82101, DIN 82016 ect. -

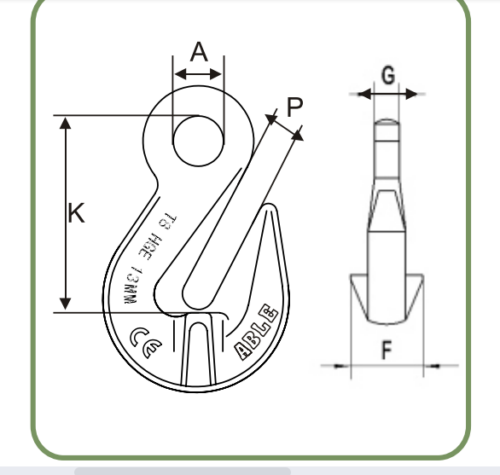

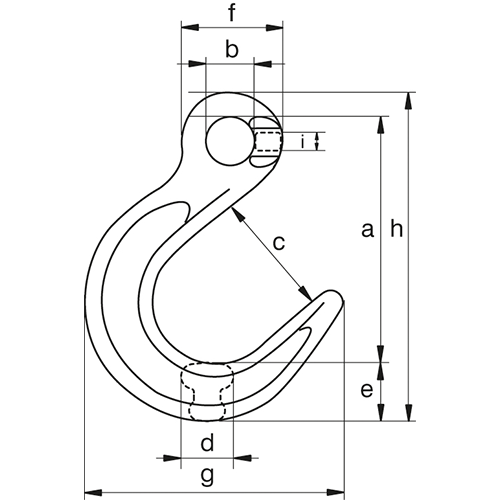

Instructions for use Lifting hooks should be inspected before use to ensure that:

Instructions for use Lifting hooks should be inspected before use to ensure that:- all markings are legible;

- a hook with the correct WLL has been selected. Refer to the EN 818 standard for Chain Slings for further details;

- the latch is present;

- the latch is functional;

- the bolt, nut or any other locking system cannot vibrate out of position;

- the hook is never side-, tip- or back- loaded;

- swivel hooks may not rotate under load;

- the hooks may not be heat treated as this may affect their WLL;

- never modify, repair or reshape a hook by machining, welding, heating or bending as this may affect the WLL;

- hooks are free from nicks, gouges and cracks;

-

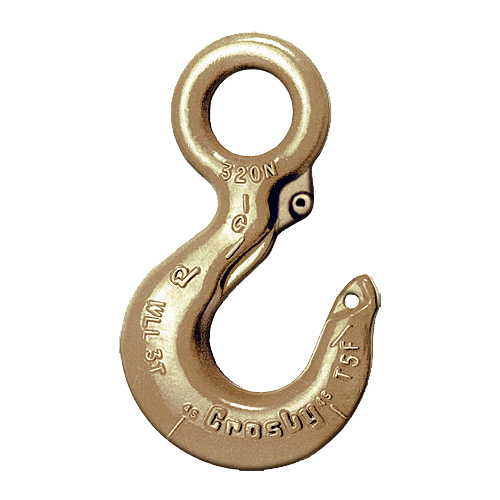

All Crosby 320 Eye Hoist Hooks incorporate the following features:

All Crosby 320 Eye Hoist Hooks incorporate the following features:- The most complete line of Eye hoist hooks.

- Available in carbon steel and alloy steel.

- Designed with a 5:1 Design Factor for (Carbon Steel); 4.5:1 Design Factor for 30t - 60t (Alloy Steel).

- Eye hooks are load rated.

- Proper design, careful forging and precision controlled quenched and tempering give maximum strength without excessive weight and bulk.

- Every Crosby Eye Hook has a pre-drilled cam which can be equipped with a latch. Even years after purchase of the original hook, latch assemblies can be added. (See pages 123 - 125)

- Chemical analysis and tensile tests performed on each PIC to verify chemistry and mechanical properties.

- Type Approval certification in accordance with ABS 2007 Steel Vessel Rules 1-11-17.7 and ABS Guide for Certification on Cranes available. Certificates available when requested at time of order and may include additional charges.

- Hoist hooks incorporate two types of strategically placed markings forged into the product which address two (2)

- Deformation Indicators and Angle Indicators (see following page for detailed definition).

-

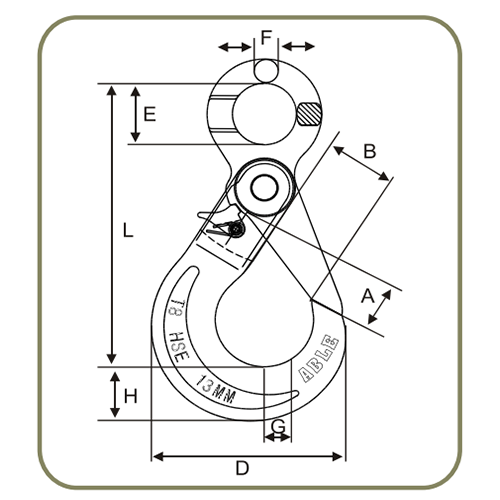

- Hooks are used in lifting systems as a connection between the load to be lifted and the wire rope or chain slings

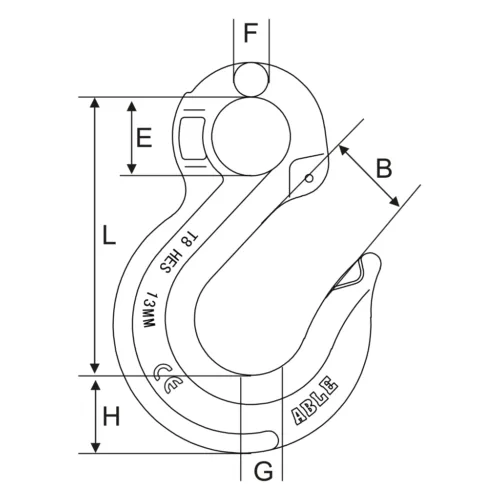

- The unique design of the Ableforge Safety Hook allows it to be easily closed with one hand, or will close itself when the load is engaged. Once under load, it will not disengage even if the load is temporarily set down. When the load is released, the latch is simply opened by pressing the release trigger, and stays open, making the hookup very easy.

-

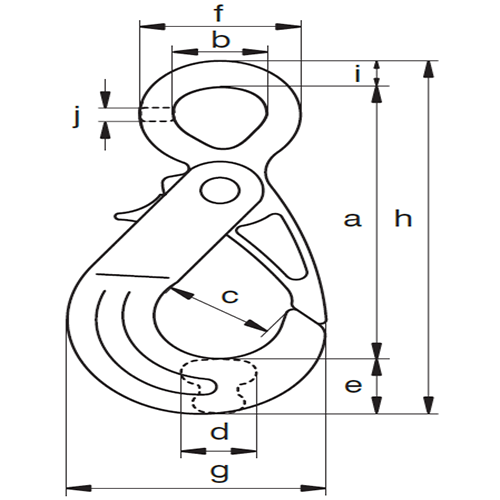

Instructions for use Lifting hooks should be inspected before use to ensure that:

Instructions for use Lifting hooks should be inspected before use to ensure that:- all markings are legible;

- a hook with the correct WLL has been selected. Refer to the EN 818 standard for Chain Slings for further details;

- the latch is present;

- the latch is functional;

- the bolt, nut or any other locking system cannot vibrate out of position;

- the hook is never side-, tip- or back- loaded;

- swivel hooks may not rotate under load;

- the hooks may not be heat treated as this may affect their WLL;

- never modify, repair or reshape a hook by machining, welding, heating or bending as this may affect the WLL;

- hooks are free from nicks, gouges and cracks;

-

- Hooks are used in lifting systems as a connection between the load to be lifted and the wire rope or chain slings

- The Ableforge Sling Hook is a versatile, general purpose hook suitable for most slinging applications and has the added advantage of safety latch kits, readily available, for converting it into an Ableforge safety hook.